The Byford Dolphin incident stands as one of the most tragic and shocking accidents in the history of offshore oil drilling. Occurring on November 5, 1983, this catastrophic event claimed the lives of five men aboard the Byford Dolphin, a semi-submersible drilling rig stationed in the North Sea. This incident not only shook the oil and gas industry but also highlighted the dangers faced by workers in one of the world's most challenging and hazardous environments. The Byford Dolphin incident remains a somber reminder of the importance of safety protocols and the devastating consequences of negligence in high-risk industries.

Located off the coast of Norway, the Byford Dolphin rig was operated by Dolphin Drilling, a company known for its pioneering work in offshore exploration. The rig was designed to withstand the harsh conditions of the North Sea, but the events of that fateful day exposed vulnerabilities in its safety systems. The tragedy occurred during a routine operation when a catastrophic failure of a diving bell decompression chamber led to an explosive decompression. This incident became a turning point for safety regulations in offshore drilling operations.

As news of the Byford Dolphin incident spread, it sparked widespread concern and scrutiny of safety practices in the oil and gas industry. Investigations revealed a series of lapses and technical failures that contributed to the disaster. The lessons learned from the Byford Dolphin incident have since been used to implement stricter safety measures and improve the design of offshore drilling equipment, ensuring that such a tragedy never happens again. This article delves into the details of the incident, its causes, and its lasting impact on the industry.

Read also:Exploring The Cast Of Mike Amp Molly A Deep Dive Into The Beloved Sitcom

Table of Contents

- What Happened During the Byford Dolphin Incident?

- Who Were the Victims of the Tragedy?

- What Caused the Explosive Decompression?

- How Did the Industry Respond to the Incident?

- Why Is the Byford Dolphin Incident Still Relevant Today?

- The Investigation and Findings

- Safety Measures Implemented After the Incident

- The Impact on Offshore Workers

- Lessons Learned from the Tragedy

- Conclusion: The Legacy of the Byford Dolphin Incident

What Happened During the Byford Dolphin Incident?

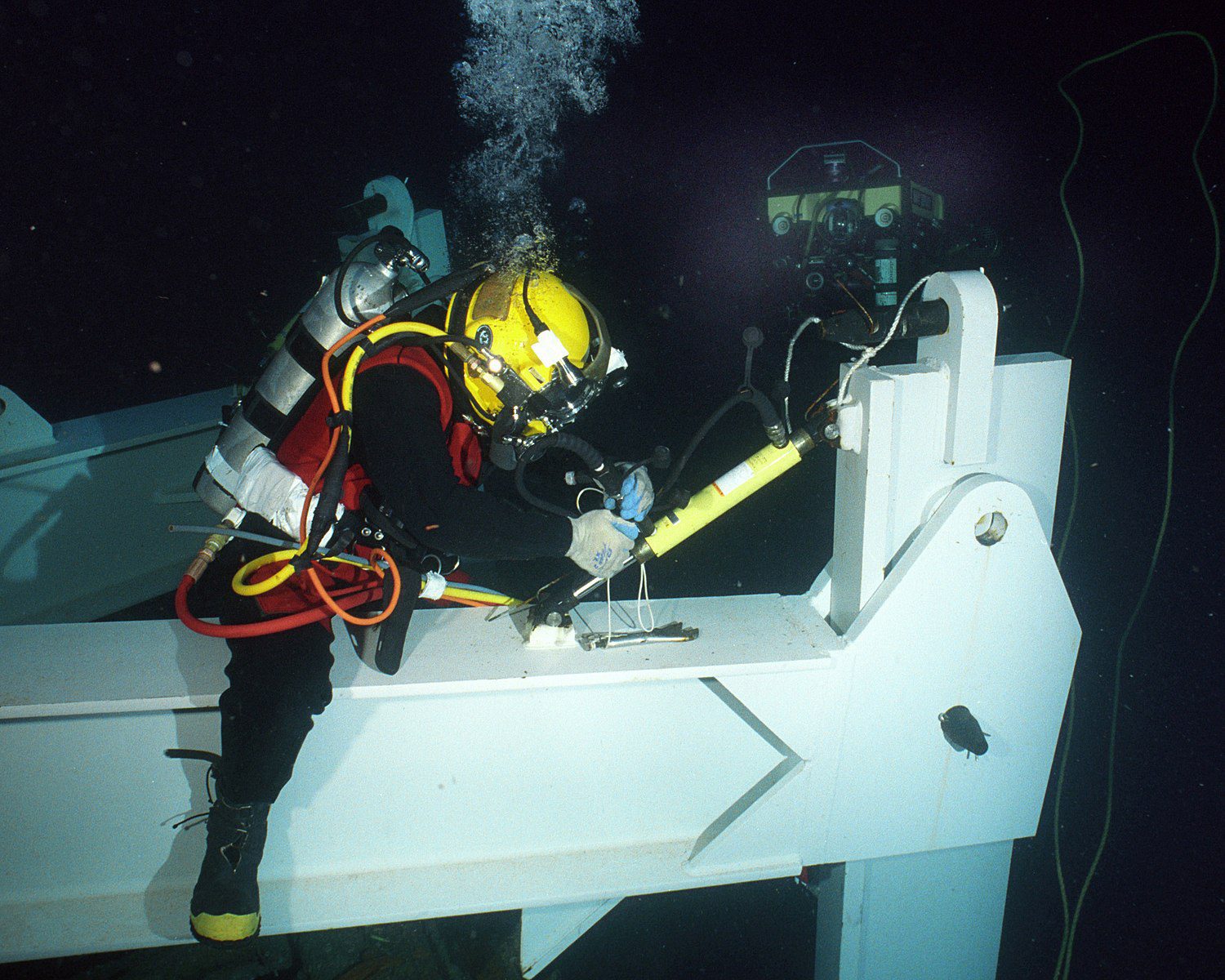

The Byford Dolphin incident unfolded during a routine operation involving the transfer of divers from a diving bell to the rig's decompression chamber. At the time, the rig was conducting drilling operations in the North Sea, and the divers were part of a team responsible for underwater maintenance and inspection. The process required precise coordination and adherence to safety protocols to prevent accidents. However, a catastrophic failure occurred when the chamber's hatch opened prematurely, causing explosive decompression.

The explosive decompression resulted in a sudden and violent release of pressure, leading to the deaths of five men. Two of the victims were inside the diving bell, while three were in the chamber. The force of the decompression was so intense that it caused severe injuries, including the tragic disintegration of one of the divers. The incident sent shockwaves through the oil and gas industry, prompting immediate investigations and calls for improved safety measures.

Witnesses on the rig described the scene as chaotic and horrifying. The sound of the explosion was heard across the rig, and the aftermath left workers traumatized. The Byford Dolphin incident highlighted the dangers of working in high-pressure environments and underscored the need for rigorous safety protocols to protect workers.

Who Were the Victims of the Tragedy?

The victims of the Byford Dolphin incident were experienced professionals dedicated to their work in the offshore oil and gas industry. Their lives were tragically cut short due to the catastrophic failure of the decompression chamber. Below is a table summarizing the personal details and bio data of the victims:

| Name | Age | Nationality | Role |

|---|---|---|---|

| William Crammond | 32 | British | Diver |

| Stephen Bohane | 26 | British | Diver |

| John MacLeod | 33 | British | Diver |

| Robert Davies | 35 | British | Chamber Operator |

| James Barber | 29 | British | Chamber Operator |

These individuals were highly skilled and trained professionals who played a crucial role in the success of offshore operations. Their loss was deeply felt by their families, colleagues, and the broader industry. The tragedy served as a stark reminder of the risks faced by workers in the offshore oil and gas sector.

What Caused the Explosive Decompression?

The explosive decompression during the Byford Dolphin incident was caused by a combination of technical failures and human error. Investigations revealed that the hatch connecting the diving bell to the decompression chamber opened prematurely, allowing high-pressure air to escape rapidly. This sudden release of pressure created a catastrophic chain reaction, leading to the deaths of the five men.

Read also:Monica Geller The Iconic Character From Friends That Defined A Generation

Several factors contributed to the failure of the hatch mechanism. First, there was a lack of proper interlocking systems to prevent the hatch from opening under pressure. Second, inadequate training and communication among the crew led to misunderstandings about the status of the chamber. Finally, the design of the decompression chamber itself was identified as a critical flaw, as it did not have sufficient safeguards to prevent such an incident.

The Byford Dolphin incident exposed significant gaps in safety protocols and equipment design, prompting a reevaluation of industry standards. It became clear that improvements were needed to prevent similar tragedies in the future.

How Did the Industry Respond to the Incident?

In the aftermath of the Byford Dolphin incident, the oil and gas industry took immediate steps to address the safety concerns raised by the tragedy. Companies operating in the North Sea and other offshore regions implemented stricter safety protocols and invested in advanced technology to prevent similar accidents. The incident served as a wake-up call for the industry, highlighting the need for continuous improvement in safety standards.

One of the key responses was the introduction of improved interlocking systems for diving bell and decompression chamber hatches. These systems ensured that hatches could not be opened unless the pressure was equalized, reducing the risk of explosive decompression. Additionally, training programs for offshore workers were enhanced to emphasize the importance of communication and adherence to safety protocols.

The Byford Dolphin incident also led to increased collaboration between industry stakeholders, regulatory bodies, and safety organizations. Joint efforts were made to develop comprehensive guidelines and standards for offshore operations, ensuring that the lessons learned from the tragedy were applied across the industry.

Why Is the Byford Dolphin Incident Still Relevant Today?

Decades after the Byford Dolphin incident, its relevance remains undiminished. The tragedy continues to serve as a powerful reminder of the importance of safety in high-risk industries. While significant progress has been made in improving safety standards, the lessons learned from the incident are still applicable to modern offshore operations.

One reason the Byford Dolphin incident remains relevant is its impact on safety culture. The tragedy highlighted the need for a proactive approach to safety, where potential risks are identified and mitigated before they can lead to accidents. This shift in mindset has led to the development of robust safety management systems that prioritize worker safety above all else.

Furthermore, the Byford Dolphin incident underscores the importance of learning from past mistakes. By studying the causes and consequences of the tragedy, the industry has been able to implement measures that prevent similar incidents from occurring. This ongoing commitment to safety ensures that the legacy of the Byford Dolphin incident continues to shape the future of offshore operations.

The Investigation and Findings

Following the Byford Dolphin incident, a thorough investigation was conducted to determine the causes of the tragedy. The investigation involved multiple stakeholders, including regulatory bodies, safety experts, and representatives from Dolphin Drilling. The findings revealed a combination of technical failures, design flaws, and human error that contributed to the catastrophic event.

One of the key findings was the lack of proper interlocking mechanisms on the chamber hatch. This design flaw allowed the hatch to open under pressure, leading to the explosive decompression. Additionally, the investigation identified inadequate training and communication as contributing factors, as crew members were not fully aware of the risks associated with the operation.

The findings of the investigation led to significant changes in safety regulations and equipment design. These changes have had a lasting impact on the industry, ensuring that the lessons learned from the Byford Dolphin incident are applied to prevent future tragedies.

Safety Measures Implemented After the Incident

In response to the Byford Dolphin incident, a series of safety measures were implemented to enhance the safety of offshore operations. These measures included the introduction of advanced interlocking systems for diving bell and decompression chamber hatches, improved training programs for workers, and the development of comprehensive safety guidelines.

- Interlocking Systems: New interlocking systems were designed to prevent hatches from opening unless the pressure was equalized, reducing the risk of explosive decompression.

- Training Programs: Enhanced training programs were introduced to ensure that workers were fully aware of the risks and safety protocols associated with their roles.

- Safety Guidelines: Comprehensive safety guidelines were developed in collaboration with industry stakeholders to establish best practices for offshore operations.

These measures have significantly improved the safety of offshore operations, reducing the likelihood of similar incidents occurring in the future.

The Impact on Offshore Workers

The Byford Dolphin incident had a profound impact on offshore workers, both in terms of their safety and their perception of the risks associated with their jobs. The tragedy highlighted the dangers of working in high-pressure environments and underscored the need for continuous improvement in safety standards.

For many offshore workers, the incident served as a wake-up call, prompting them to demand better safety measures and training programs. The tragedy also led to increased awareness of the importance of mental health and well-being in high-risk industries, as workers grappled with the trauma of the event.

Overall, the Byford Dolphin incident played a pivotal role in shaping the safety culture of the offshore oil and gas industry, ensuring that worker safety remains a top priority.

Lessons Learned from the Tragedy

The Byford Dolphin incident taught the industry valuable lessons about the importance of safety, communication, and continuous improvement. These lessons have been applied to enhance the safety of offshore operations and prevent similar tragedies from occurring in the future.

- Safety First: The incident emphasized the need for a proactive approach to safety, where potential risks are identified and mitigated before they can lead to accidents.

- Communication is Key: Effective communication among crew members is essential to ensure that everyone is aware of the risks and safety protocols associated with their roles.

- Continuous Improvement: The industry must remain committed to continuous improvement, adopting new technologies and practices to enhance safety standards.

By applying these lessons, the industry has been able to create a safer working environment for offshore workers, ensuring that the legacy of the Byford Dolphin incident continues to shape the future of the industry.

Conclusion: The Legacy of the Byford Dolphin Incident