When it comes to electrical installations, safety and compliance are non-negotiable. One of the most critical aspects of ensuring safe electrical systems is the proper use of underground conduits as per the National Electrical Code (NEC). NEC underground conduit standards are designed to protect both the wiring and the surrounding environment, ensuring that electrical systems remain efficient and hazard-free. Whether you're a homeowner, contractor, or electrician, understanding these guidelines is essential for any project involving underground electrical installations.

NEC underground conduit regulations provide a framework for safely installing and maintaining electrical conduits beneath the ground. These standards address factors such as depth requirements, material specifications, and environmental considerations. By adhering to these guidelines, you can prevent potential issues like electrical faults, water damage, or accidental damage during excavation. Proper installation not only ensures compliance but also extends the lifespan of the electrical system while minimizing risks.

As technology evolves and electrical demands grow, the importance of NEC underground conduit standards cannot be overstated. These guidelines are updated regularly to reflect advancements in materials, construction techniques, and safety protocols. By staying informed about the latest NEC requirements, you can ensure that your projects meet the highest standards of safety and efficiency. This article will delve into the key aspects of NEC underground conduit, answering common questions and providing actionable insights for professionals and DIY enthusiasts alike.

Read also:Unraveling The Mystery Of The First Fast And Furious Film A Deep Dive Into Its Origins And Impact

- What is NEC Underground Conduit?

- Why is NEC Underground Conduit Important?

- What Are the Material Options for NEC Underground Conduit?

- How Deep Should NEC Underground Conduit Be Installed?

- Common Mistakes to Avoid with NEC Underground Conduit

- How to Choose the Right NEC Underground Conduit?

- Benefits of Using NEC-Compliant Underground Conduit

- Maintenance Tips for NEC Underground Conduit

- Frequently Asked Questions About NEC Underground Conduit

- Conclusion

What is NEC Underground Conduit?

NEC underground conduit refers to the protective tubing used to house electrical wiring beneath the ground. These conduits are designed to shield wires from environmental factors such as moisture, temperature fluctuations, and physical damage. The NEC provides specific guidelines for the installation and maintenance of these conduits to ensure they function effectively and safely.

The primary purpose of NEC underground conduit is to protect electrical wiring from external threats while maintaining the integrity of the electrical system. Conduits can be made from a variety of materials, including PVC, metal, and composite materials, each with its own advantages and limitations. The choice of material often depends on the specific requirements of the project, such as soil conditions, load-bearing capacity, and environmental exposure.

Why is NEC Underground Conduit Important?

NEC underground conduit plays a crucial role in ensuring the safety and reliability of underground electrical systems. Without proper conduit installation, electrical wiring is vulnerable to damage from moisture, corrosion, and accidental impacts. This can lead to costly repairs, system failures, and even safety hazards like electrical fires or shocks.

By adhering to NEC standards, contractors and electricians can ensure that their installations meet the highest safety benchmarks. These standards are developed through extensive research and testing, making them a trusted resource for professionals in the electrical industry. Compliance with NEC underground conduit guidelines not only protects the installation but also enhances the overall efficiency of the electrical system.

What Are the Material Options for NEC Underground Conduit?

Choosing the right material for NEC underground conduit is essential for ensuring long-term performance and compliance. Here are some of the most common options:

- PVC Conduit: Lightweight, corrosion-resistant, and cost-effective, PVC is a popular choice for many applications.

- Metal Conduit: Offers superior strength and durability, making it ideal for high-load environments.

- Rigid Non-Metallic Conduit (RNC): Combines the benefits of flexibility and resistance to environmental factors.

- Fiberglass Conduit: Known for its high strength-to-weight ratio and resistance to chemicals.

Each material has its own set of advantages and limitations, so it's important to evaluate the specific needs of your project before making a decision.

Read also:Rip Dr Jeff Remembering The Legacy Of Rocky Mountain Vets Passing

How Deep Should NEC Underground Conduit Be Installed?

The depth at which NEC underground conduit should be installed depends on several factors, including the type of conduit, the voltage of the wiring, and local building codes. Generally, the NEC recommends a minimum burial depth of 18 inches for residential applications and 24 inches for commercial installations. However, these guidelines may vary based on specific circumstances.

Proper burial depth is critical for protecting the conduit from external forces such as traffic loads, soil erosion, and frost heave. Failing to adhere to these depth requirements can result in damage to the conduit and the wiring it contains, leading to costly repairs and potential safety hazards.

Common Mistakes to Avoid with NEC Underground Conduit

Even experienced professionals can make mistakes when working with NEC underground conduit. Here are some common pitfalls to avoid:

- Improper Depth: Failing to bury the conduit at the correct depth can lead to damage and non-compliance.

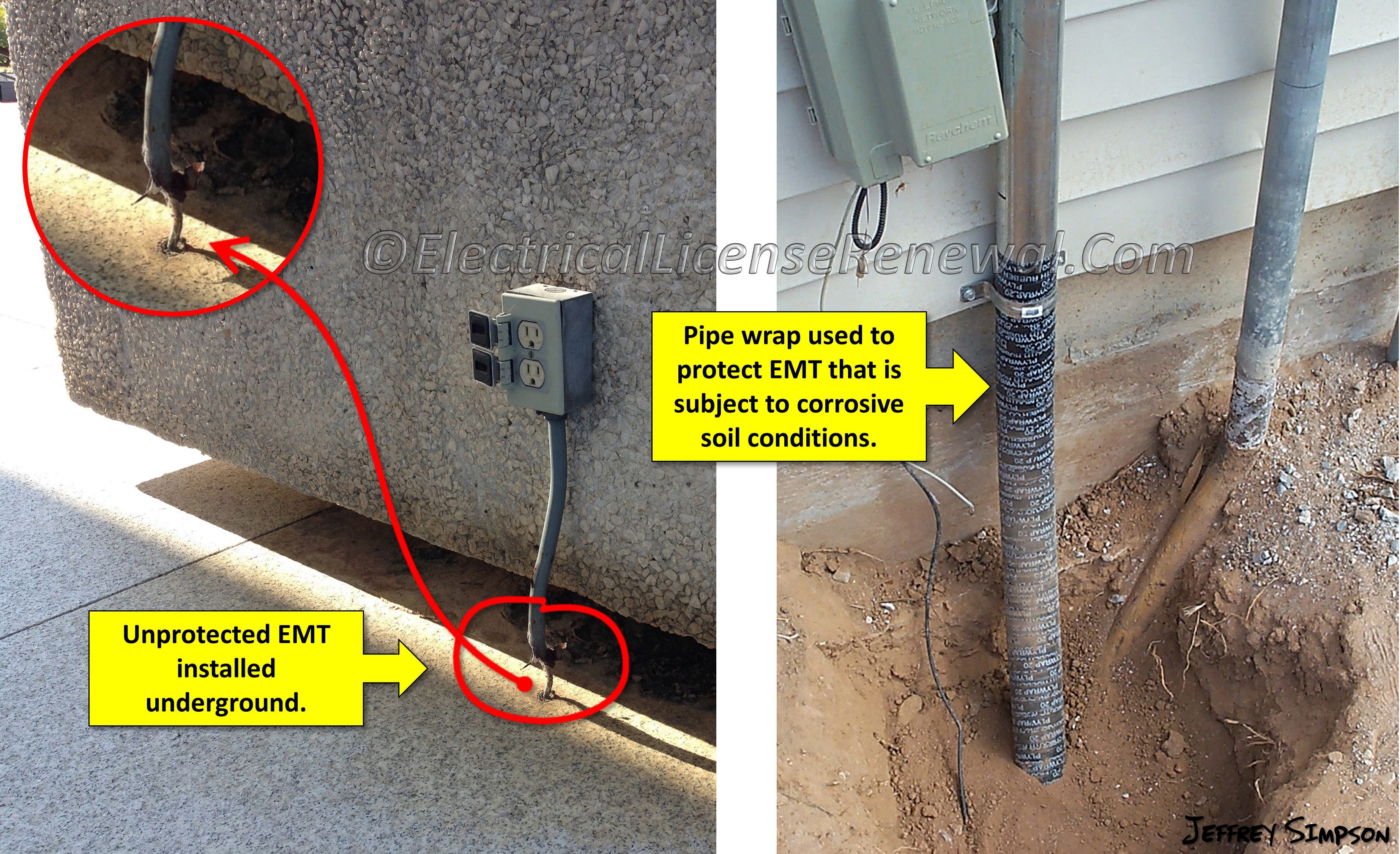

- Incorrect Material Selection: Using the wrong material for the environment can result in premature failure.

- Poor Sealing: Inadequate sealing of conduit joints can allow moisture to enter, causing corrosion and electrical faults.

- Ignoring Local Codes: Local building codes may have additional requirements beyond the NEC standards.

Avoiding these mistakes requires careful planning, attention to detail, and a thorough understanding of NEC underground conduit guidelines.

How to Choose the Right NEC Underground Conduit?

Selecting the appropriate NEC underground conduit for your project involves evaluating several factors. Consider the following questions to guide your decision:

- What is the voltage and current load of the wiring?

- What are the soil and environmental conditions?

- What is the expected lifespan of the installation?

- Are there any local codes or regulations that apply?

By answering these questions, you can narrow down your options and choose a conduit that meets your project's specific needs.

Benefits of Using NEC-Compliant Underground Conduit

Using NEC-compliant underground conduit offers numerous advantages, including:

- Enhanced Safety: Reduces the risk of electrical hazards and system failures.

- Long-Term Durability: Ensures the longevity of the electrical system by protecting wiring from environmental damage.

- Cost Savings: Prevents costly repairs and replacements by minimizing the risk of damage.

- Compliance: Ensures adherence to legal and regulatory requirements, avoiding potential fines or penalties.

These benefits make NEC underground conduit a smart investment for any electrical installation project.

Maintenance Tips for NEC Underground Conduit

Proper maintenance is essential for ensuring the long-term performance of NEC underground conduit. Here are some tips to keep in mind:

- Regularly inspect the conduit for signs of damage or wear.

- Ensure that all joints and connections are properly sealed to prevent moisture ingress.

- Clear debris and vegetation from the area around the conduit to prevent soil erosion.

- Consult a professional if you notice any issues or irregularities.

By following these maintenance practices, you can extend the lifespan of your NEC underground conduit and ensure its continued effectiveness.

Frequently Asked Questions About NEC Underground Conduit

Here are some common questions and answers about NEC underground conduit:

What is the NEC code for underground conduit?

The NEC provides specific guidelines for underground conduit installation in Article 300, which covers wiring methods and materials.

Can I use PVC for NEC underground conduit?

Yes, PVC is a commonly used material for NEC underground conduit due to its durability and resistance to moisture.

How do I know if my conduit meets NEC standards?

Check the conduit's labeling and documentation to ensure it is rated for underground use and complies with NEC requirements.

What happens if I don't follow NEC underground conduit guidelines?

Failing to comply with NEC standards can result in safety hazards, system failures, and legal consequences.

Conclusion

NEC underground conduit is a vital component of any underground electrical installation. By adhering to NEC guidelines, you can ensure the safety, efficiency, and longevity of your electrical systems. Whether you're a homeowner or a professional contractor, understanding these standards is essential for successful project outcomes. By choosing the right materials, following proper installation practices, and performing regular maintenance, you can maximize the benefits of NEC underground conduit and avoid common pitfalls.